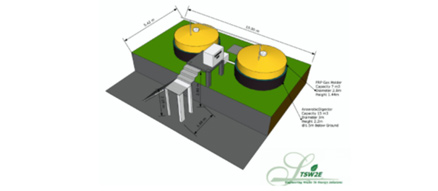

Biogas Plant works on the basis of Anaerobic Digestion or Biomethanation principle. i.e. in the absence of air, biodegradable waste is converted to Methane, Carbon Dioxide by specialized bacteria. Biogas plants treat biodegradable waste thereby maintaining a clean, hygienic, pollution free environment. Biogas generated is directionally proportional to the quantity of solid waste loaded per day. Part of the sludge produced as byproduct of the process, can be drained out annually and used readily as good fertilizer.

A typical biogas plant converts volatile solids part of biodegradable waste to Methane and Carbon Dioxide. Normal biogas plants do not converter the fiber part of the biodegradable waste. Some specialized technology like double stage biogas plants generates biogas from biodegradable fraction of Municipal Solid Waste (MSW). Based on the input waste to the anaerobic digester, the biogas produced comprises of 50-80% Methane and 20-50 % Carbon Dioxide. Biogas can be utilized as replacement to LPG i.e. for cooking or on larger scales for power generation.

Biogas plants are considered to be a pollution prevention option. As these plants prevent open release of harmful gases like methane and open purification/ decay of waste, which is a nuisance to Public. Open release of methane is harmful to the environment, as Methane (CH4) is considered to be 29 times harmful than Carbon Dioxide (CO2), in terms of Global Warming Potential (GWP). Also, there is high chance that this waste may mix with rainwater and pollute the nearby water bodies. Thus, a biogas plant effectively utilizes waste for energy generation, rather than polluting the environment.

Bioremediation is an advanced technology used for removal of organic as well as inorganic pollutants from polluted soil and water.

First, a group of pollution tolerant bacteria suitable for polluted location is identified and isolated. A team of bacterial colonies are developed from the selected pollution tolerant ones. This specialized bacterial consortium is reintroduced to the polluted area in large quantities for treatment of contaminants. Since, these bacterial colonies are naturally selected from the environment, there reintroduced microbes possess no harmful effects to the existing natural flora and fauna. Bioremediation is found suitable to effectively handle Industrial Effluent Pollution, Petroleum pollution etc.

TeamSustain had tested few microbial inoculums for treatment of yellow tallow in oil and grease traps.

Planet & People friendly solution to remove harmful chemicals from contaminated air, soil and water

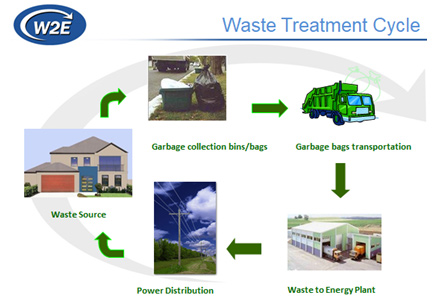

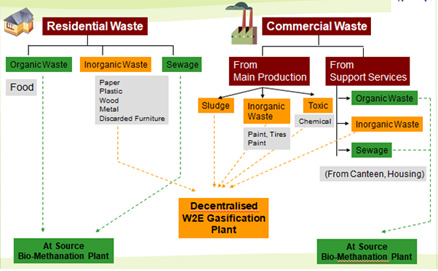

We have developed technology to provide waste-to-energy services and products to service specific industry needs. We will service the market niche to provide turnkey waste-to-energy systems from 200kW to 30 MW in size. This includes small scale systems in remote locations and larger solid waste disposal facilities providing electricity to the Grid.

Our technology aims at waste disposal (primary) and to distribute energy generated locally, using domestic waste resources, and thus provide energy security and waste disposal solutions. By designing renewable energy strategies for local waste generators or collection locations, we provide a simple path to create energy and avoid typical disposal practices using the best elements of proven gasification technologies.

| It has the following salient features | |

|---|---|

| Practical | A small size turnkey package is simple installation, with custom integration into existing infrastructure |

| Reliable | The plant has 99.9% uptime in typical use. |

| Efficient | Processing almost any type of waste materials eliminated extra processing steps |

| Safe | System runs at ambient pressure and produces CO2, Water Vapor, Ash and Metals for recovery and use |

| Environmental | Produces minimal to no contaminants of concern. It replaces old systems that produce carcinogens, contaminate water systems and release greenhouse gases. |

| Flexible | Can process varied waste streams in combination without system modification. Gasification system are able to process materials of varying sizes and combinations. General sizing to < 6” is appropriate and allows for even process flow through the materials handling system and into the core processing unit. This flexibility allows for Municipal Solid Waste (MSW) applications to work quickly and efficiently. |

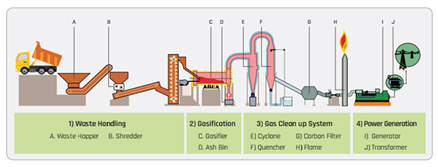

Mixture of materials enter the vessel through a feed system, the stream is reacted, using oxygen or air, and heat, the conversion process produces ash, which is removed to a hopper for recycling, and syngas, which is a gas comprised of CO and H2, which is then cleaned through a gas clean up process, which yields a syngas that is cleaner burning than natural gas.